We’re on LinkedIn!

Connect with WCS Environmental Engineering Safe Efficient Compliance

Danesmoor wastewater treatment works (7000 PE), required a bespoke solution to overcome challenging on-site access.

The tertiary treatment plant is designed to treat the residual ammonia from the wastewater being discharged to a watercourse. As part of a £2million upgrade at Yorkshire Water’s site, the revision was imposed to meet the latest regulations on water quality set by European legislation (the Freshwater Fish Directive).

The Yorkshire Water contracts delivery partner Byzac Entec commissioned the solution after a formal tendering process against the Yorkshire Water asset standard and taking into account whole life costs.

Modular SAF design:

The unit had to handle 50 l/sec FFT (almost twice the average) meaning that something out of the ordinary had to be devised. The 11.7m length, 4.6m tall and 2.9m wide N-SAF unit was built off-site prior to being transported to Danesmoor wastewater treatment works; a process being favoured for lowering health and safety risks on-site.

Design engineers came up with eight modular tanks manufactured from steel, as per the specification, which were assembled off-site in the factory.

The units had to then be taken apart for transportation to avoid overhead electric cables and fit down narrow country lanes. The tanks had to be lifted, rotated and placed onto a prepared concrete slab when on-site.

This process solution of a factory ‘kit’ build meant that fewer workers were required at Yorkshire Water’s site, in turn minimising the risk of health and safety and quality control.

All eight modular tanks were erected on site within two days. The units were supplied, delivered and installed successfully to improve the discharge from Danesmoor wastewater treatment works with no safety implications.

The eight steel modular tertiary N-SAF tanks designed by the engineers were installed ahead of time and on budget.

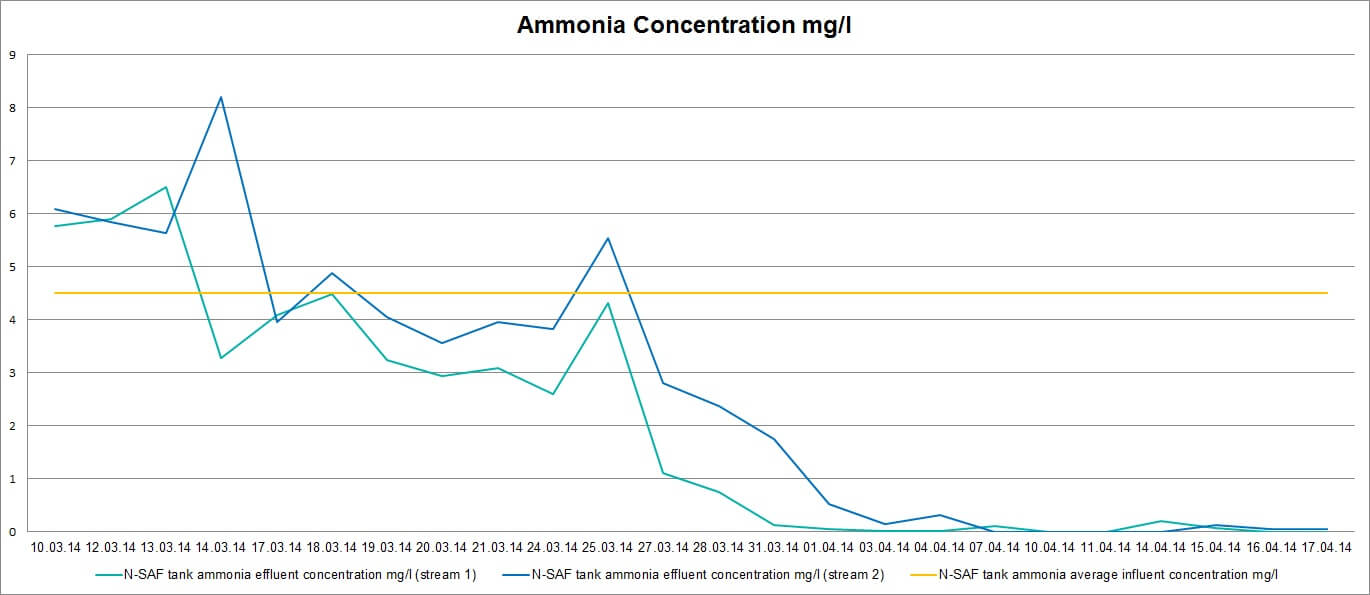

Within one month, the modular N-SAF was fully operational and achieving 0 mg/l ammonia effluent.

One of the obvious challenges of running an animal shelter, including kennels and catteries, is the need to dispose of ...

Healthcare facilities such as care homes and hospitals produce higher volumes of wastewater and have more complex ...

What is off mains drainage and sewage treatment? Up to 3% of properties in the UK have off-mains drainage and sewage ...

Connect with WCS Environmental Engineering Safe Efficient Compliance

WCS Group is a trading name for WCS Environmental Ltd, registered in England and Wales (Number 02184649) at 20 Grosvenor Place, London, SW1X 7HN. Head Office – 17 Wheatstone Court, Waterwells Business Park, Gloucester, GL2 2AQ. WCS Group is a Marlowe Critical Services Company owned by Marlowe plc. 2024© WCS Environmental Ltd.